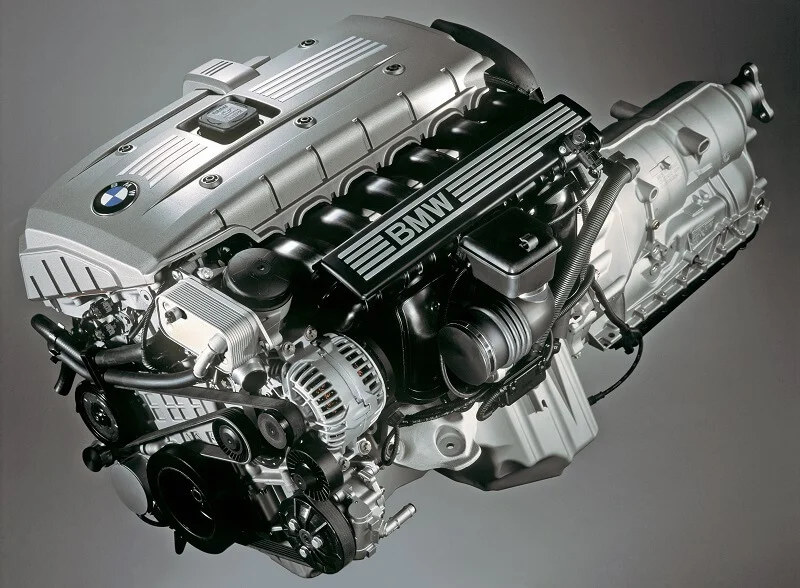

Various types of features and components installed in the BMW N51 engine include sensors that enable the smooth running of the BMW N51 engine for maximum performance. One of the intricate components is the crankshaft sensor, which is an important factor in this symphony of technology. This seemingly inconspicuous but vital component aids the BMW N51 engine management system in its capacity to detect the speed of the engine as well as its position to apply the right measure of fuel and timing of ignition. But what can go wrong when it is the crankshaft sensor that is not in good working condition in the BMW N51 engine?

In this article, I will attempt to outline what one would expect from the N51 engine in such conditions, employing the knowledge and experiences that I have gained.

Common issues with the BMW N51 engine can often be traced back to its crankshaft sensor, indicating how crucial this component is for optimal performance.

Table of Contents

The Role of the Crankshaft Sensor

The study of the crankshaft installation requires attention before comprehending the operation of the crankshaft sensor. The sensor determines the crankshaft rotation speed and position during its movement. The engine control unit (ECU) receives data that enables it to synchronize between engine fuel injection and ignition sequences.

Consequently, if the crankshaft sensor in the BMW N51 engine fails, the overall functioning of the engine will be compromised.

The operation of the BMW N51 engine faces severe problems when the relay associated with this sensor gets spoiled.

Initial Engine Reactions

In such scenarios where the crankshaft sensor fails in the BMW N51 engine, the driver may experience significant issues.

Misfires and Stalling

Nonetheless, when the crankshaft sensor is bad, the engine will always show noticeable signs that it is in trouble. This is something I was once exposed to while my friend was driving his BMW car and the crankshaft sensor developed a problem. The above is something that I have seen firsthand on a friend’s BMW with developing a problem with the crankshaft sensor.

What you will first find is that it tends to misfire often and this is because its electron configuration is not fully stable. Misfires take place since the ECU fails to find the right time to ignite the spark plug. This results in the engine running roughly and, at worst, stalling from the road due to the loss of combustion energy.

Check Engine Light

That is why ensuring the crankshaft sensor in the BMW N51 engine is functioning correctly is paramount for a smooth driving experience.

Long-term neglect of the crankshaft sensor issues in the BMW N51 engine can lead to serious complications.

One of the most likely immediate responses is that it leads to the activation of the check engine light. This light is the signal that the engine requires some attention or something is wrong with it. As soon as the check engine light turns on, it is possible to use an OBD-II scanner and extract the code that usually indicates that the crankshaft sensor is bad.

Loss of Power

Understanding how the crankshaft sensor affects the BMW N51 engine is crucial for proper maintenance.

The absence of a properly functioning crankshaft sensor may also cause a considerable depletion of power output. This way, when the engine rhythm is disrupted, it cannot produce the same level of power it used to. Driving in this state is uncomfortable because the car’s engine is not as lively and powerful as it is used to. Sometimes, having engaged in test driving my friend’s car with a bad crankshaft sensor, I have felt that I was more like trying to accelerate the car.

Additionally, drivers should monitor symptoms that may indicate crankshaft sensor failure in the BMW N51 engine.

Long-Term Effects

Erratic Idle

Regular diagnostics of the crankshaft sensor in your BMW N51 engine could prevent long-term damage.

Addressing crankshaft sensor issues promptly in your BMW N51 engine will help maintain its performance.

Eventually, the crankshaft sensor’s problem that has not been rectified will cause the car to idle roughly. The engine could just stop while the car is static or vibrate roughly all the time when the car is idle. This can be so irritating and at times may lead to accidents, especially when it occurs while in traffic. For instance, I had once been driving in my car only to develop a mechanical failure at a signal and was surrounded by other vehicles that were speeding on the road.

In conclusion, the proper functioning of the crankshaft sensor is vital for the BMW N51 engine’s overall performance.

Fuel Efficiency

Also, one of the more serious problems associated with the crankshaft sensor is the badly affected fuel economy. Some of the effects of the misfire of the ECU with regard to fuel injection and ignition timing can include the following: Inability to burn the fuel completely. This is detrimental in the sense that not only is there pollution of the environment but also the fuel economy is affected by this. This is evidence that mileage decreased significantly and was reputed by several miles per gallon after using the sensor for a few days with a problem.

What Can You Do?

By regularly checking the crankshaft sensor in the BMW N51 engine, drivers can prevent severe issues.

Diagnostics

It will be wise to begin by diagnosing it if you suspect the crankshaft sensor of your BMW N51 engine to be the problem. It is plausible to use an OBD-II scanner to diagnose the activity of the crankshaft sensor by revealing error codes. This is important before coming to certain conclusions or acquiring high costs for a repair that wasn’t even necessary.

Replacement

When the diagnostics indicate the crankshaft sensor as being bad, then a replacement of the same usually cures the problem. This should ideally be done by a mechanic, however, it is not a very complex or difficult process to change it, provided you have the necessary tools and mechanical skills. I once had to help a friend repair one of his BMW engines, and specifically, I helped him change the crankshaft sensor; although it was a challenging job, it was one of those straightforward jobs.

Personal Opinion: The Importance of Regular Maintenance

From my own perspective, I can conclude that the basic rule of maintenance plays a significant role in hindering problems with the entirety of the sensors, inclusive of the crankshaft sensor. This will help reduce the chances of experiencing an ‘end-of-life failure,’ hence benefiting from regular check-ups and signs that show wear and possible later breakdown. For some reason, I stand firm on maintenance schedules and any oddities regarding the vehicle’s engine.

End Note

In general, a defective crankshaft sensor on a BMW N51 engine may cause misfires or stalling of the car, power loss, and unsteady idle speed. By being aware of such potential issues, one is in a position to prevent them, which in turn will help in the productivity of the BMW vehicle. Still, getting a faulty sensor is an inconvenience but when diagnosed early and fixed, this will see your vehicle functioning as required again.

FAQ Section

What are the signs that indicate a faulty crankshaft sensor in your BMW N51 engine?

Some of the signs are misfires, stalling, illumination of check engine, power loss, idle control issues, and reduced fuel economy.

How is a car crankshaft sensor problem identified?

Get an OBD-II code reader to diagnose symptoms that can also be associated with the crankshaft sensor.

How challenging is it to replace a crankshaft sensor?

Changing a crankshaft sensor is relatively easy, but it may take some mechanic’s skills and equipment. It is a problem, which is rather safely solved with the help of a specialist.

Does it mean that if your car is driven with a bad crankshaft sensor, further damage can be caused to the vehicle?

Yes, but using a vehicle with a damaged crankshaft sensor to drive can lead to more harm to the car’s engine and it will be working awkwardly, leading to poor performance of the car.

How frequent is it to replace the crankshaft sensor?

It cannot be told how often the crankshaft sensor should be replaced, as it depends, but it must be replaced when it has begun to malfunction. Preventive and regular maintenance services make it easier to solve problems by noticing them early enough.